About Us

Why Choose Us

Capability

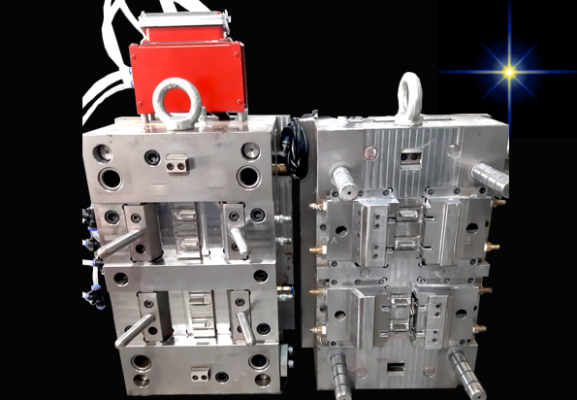

EQUIPMENT SUMARY

Quality mould/tools come from quality manufacturing assets. The machining capacity is combined with machining managements, machining process knowledge… Also human resource is One of our core competency. This enables us to maintain a consistency in delivering quality moulds and meeting customer requirements.

PROCESS

We have machines ranging from High speed CNC milling, CNC-EDM, CNC-Wirecut machine to facilitate mould and tools fabrication. Most of all are new

MATERIAL

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. Mild steel (P20, 1.2312, ...) are suitable only for prototype or very short production runs. Harden steel (NAK80, 1.2083, SKD61, DC53, ..) with proper mould design, can easily make moulds capable of 100,000 or more part life with proper mould maintenance.